Bioprocess sensors with the same precision as you.

Without sensors, your bioprocesses lack precision. They provide vital values that affect the viability and productivity of the cells and influence the analysis of active ingredients. Adding and integrating additional sensors to your bioprocess allows you to enable Process Analytical Technology (PAT) and generate more data. Plus, you can get more consistently duplicatable data and reduce the need for sampling.

A variety of sensors for every need.

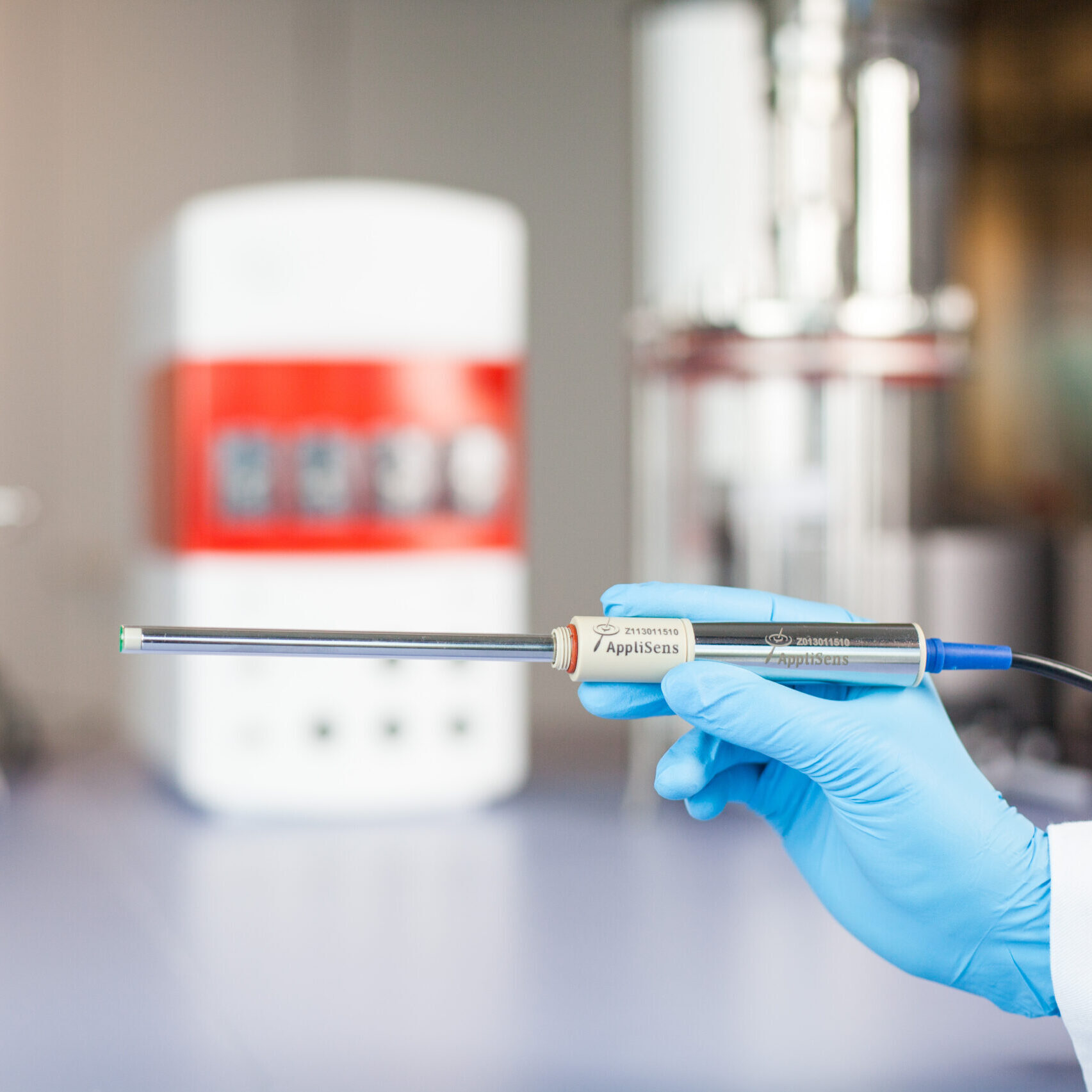

Applikon offers a number of process analytical technologies (PAT) to get the very best measurements from your process. The AppliSens range of sensors are designed for easy calibration, short response time and long-term stability to help you get the most reliable results.

Take a look at the sensors below.

The LumiSens optical DO Sensor is convenient and ready to go immediately! It can be used straight after autoclaving because no polarization is needed. It also has a longer sensor lifetime since it doesn’t need to be sterilized. The optical technology allows accurate measurements especially in the low oxygen concentration range where classic probes are less accurate. ! Plus, with no electrolytes or membranes to replace, you can also save on maintenance costs.

Need long-term, stable and accurate measurements from your bioprocess? The DO2 sensor should be your choice. It reduces the start-up time of your cultivation thanks to the autoclavable polarization module that allows the sensor to polarize while autoclaving the bioreactor system. The Applikon DO2 sensor is also easily calibrated, has short response times and optimal cleanability due to the electro-polished surface.

The AppliSens pH+ sensor is another great choice for those with a long-term biotech cultivation process. Its fixed sleeve diaphragm reduces the influence of culture medium on the pH measurement and increases the measuring accuracy and lifetime of the sensor.

If you need to measure the RedOx potential (Reduction/Oxidation) of your bioprocess, then you need the RedOx sensor. Gain accurate readings and measurements with the robust design using a tempered glass shaft. The RedOx sensor can also be used in anaerobic fermentations as an alternative to the Dissolved Oxygen sensor, which does not always give the correct process information in anaerobic situations.

Features of the AppliSens range of biotechnology sensors.

As with many other Applikon products, the AppliSens sensors are designed with every user in mind. This means they feature a robust, compact design and allow for easy setup by taking up minimal space on the bioreactor top plate.

Applikon is a full solution provider. The aim is to make your process as easy-to-use and accurate as possible. Therefore, many of our biotechnology sensors have a driver that is built-in to the Applikon controller software. This way, you can get sensor data, information (e.g. health status) and sensor operating parameters (e.g. calibration) immediately. It’s possible to have direct integration with the following sensors:

- AppliSens pH Sensor

- AppliSens DO Sensor

- AppliSens RedOx Sensor

Save investment costs and bench space without the need for an external transmitter. Plus, there’s no need for additional software, meaning easy operator training and cost saving of additional software.

The AppliSens sensors allow you to generate:

- One sample every x minutes instead of one measurement from an offline measurement per day.

- Online data, meaning fast response and full control of key process parameters.

- Accurately duplicated data because samples are measured in exactly the same way every time = no more operator to operator variation.

Customer questions and recessions

The biotechnology sensor range from Applikon can be used in the following applications:

- Fundamental

- Research

- Optimization

- Pilot Plant

- Manufacturing

- Process development

- Screening

Yes! If you need to achieve biomass measurements during your process, we can help with that. At Resea Biotec, we can provide various additional sensors so you can gain true process control and monitoring with less workload.

We offer Call Density Sensors for biomass measurement that provide both Viable Cell Density and Optical Density analysis.

Also available are the Hamilton ARC sensors that further eases your bioprocess by rethinking communication between sensors, end users and process control systems. ARC sensors omit the need for a traditional transmitter by communicating directly with the Applikon process control system.

All Applikon sensors can be connected via USB connection or direct integration:

- LumiSens Optical DO Sensor

- AppliSens DO Sensor

- AppliSens pH Sensor

Some third party additional sensors (compatible with Applikon bioreactors) are also available via USB connection:

- Hamilton DO and pH (ARC)

- Hamilton Densytee and Incyte

- Mettler Toledo pH, DO and CO2 (ISM)

- BugLab BE2100 and BugLab BE3000

- ABER Futura Biomass

- SBI Balance

- HiTec Zang Balance

- Presens optical pH/DO

It’s also possible to connect some sensors via analog connection (Note: ADDA, Analog Input License or SIP board required):

- BlueSens CO2, BlueSens O2

- BlueInOne CO2/O2

- BlueVary

- Loadcells

- FoamFighter

- Optek OD Senso

- …and more.

An important addition to your bioprocess.

Can you really get all the values and information you need right now from your standard sensors? The intelligent and optical sensors provided by Applikon are easily integrated into your system and can give you the results you need within minutes.

With the addition of further sensors like offgas, biomass and balances, you can also get even more vital information that will help your long-term cultivation.

Your bioprocess needs precision. Your bioprocess needs Applikon biotechnology sensors.