Applications

Stem cell bioreactor: revolutionizing cultivation

The Applikon small scale bioreactor leads the field in stem cell cultivation technology, presenting a sophisticated solution tailored specifically for the nuanced demands of stem cell research. This system goes beyond basic maintenance; it is engineered to adapt and respond to the evolving conditions of stem cell cultures. By integrating high-precision control systems, the bioreactor ensures that all environmental variables such as temperature, pH, and oxygen levels are optimized, thus creating ideal conditions for cell growth and safeguarding the cells' developmental potential.

How to culture stem cells with the Applikon bioreactor

Cultivating stem cells in an Applikon Mini bioreactor or Appliflex ST combines precision engineering with advanced biotechnology methods to optimize stem cell production, crucial for research and therapeutic applications. Here’s a look at how this bioreactor can enhance stem cell cultivation processes:

Initialization: Precise Environment Preparation

In the initial phase, stem cells, whether embryonic or adult-derived, are introduced into the sterile Applikon bioreactor, ensuring a contamination-free start. The culture medium, enriched with essential nutrients and growth factors, is carefully prepared to mimic the natural microenvironment of the stem cells. This step is critical to maintain the pluripotency and viability of the stem cells, setting the precondition for successful cell expansion.

Optimal Environment Regulation: Automated Control Systems

The Applikon glass and single-use bioreactor excels in creating and maintaining an optimal growth environment through its advanced control systems. Parameters, including temperature, pH, and dissolved oxygen, are meticulously regulated to meet the specific requirements of stem cell cultures. This precise control is essential to prevent unwanted differentiation and to support robust stem cell proliferation. The bioreactor's ability to maintain these conditions consistently ensures the preservation of the stem cells' pluripotent state, allowing them to develop into the desired cell types upon further induction. Although the trend of cultivating stem cells leads towards suspension cultures, microcarriers are still widely used. Microcarriers help to increase the surface area for cell culture, allowing for higher cell densities and more efficient bioprocessing.

Monitoring and Adjustment: Ensuring Quality and Consistency

Continuous monitoring is a cornerstone of successful stem cell cultivation in the Applikon bioreactor. Equipped with real-time sensors and feedback mechanisms, the bioreactor ensures that the culture conditions are always within the optimal ranges. Adjustments are made automatically, reducing the need for manual intervention and minimizing human error. This feature not only enhances the efficiency of the cultivation process but also ensures the consistency and reproducibility of stem cell batches, crucial for both research validity and therapeutic efficacy.

Stem cell expansion: scaling up with precision

The Applikon bioreactor systems address the challenge of expanding stem cell cultures while maintaining their undifferentiated state with high precision. The bioreactor facilitates a scalable platform for stem cell expansion, enabling researchers and biotechnologists to produce larger quantities of stem cells for research and therapeutic applications. By providing a controlled, reproducible environment, the bioreactor ensures that the expanded stem cells retain their characteristic properties, crucial for their eventual therapeutic use.

Advantages of using the Applikon small scale bioreactor for stem cell cultivation

- Scalability: The bioreactor's design supports the expansion of stem cell cultures to meet research and clinical demands.

- Control: Precise control over the cultivation environment minimizes the differentiation risk, ensuring the production of homogeneous stem cell populations.

- Efficiency: Automated monitoring and adjustments reduce the need for manual intervention, making the stem cell cultivation process more efficient and less labor-intensive.

The Applikon multi-use Mini bioreactor and the single-use AppliFlex ST represent a significant advancement in the field of stem cell research and therapy. By facilitating the controlled, efficient cultivation and expansion of stem cells, this bioreactor is a central tool in advancing regenerative medicine, offering hope for treating numerous conditions. For researchers and clinicians looking to leverage the full potential of stem cells, the Applikon Mini bioreactor and the AppliFlex ST provide a reliable, scalable solution, ensuring the production of high-quality stem cells for a wide range of therapeutic applications.

Feautured Products

V-Control

Developed in partnership with Emerson, V-Control is a process control platform designed as a 'one common-platform' solution for bioreactors from research to production.

V-Control offers a scalable software solution that overcomes the hurdles of scaling up.

AppliFlex ST GMP single-use bioreactor

The AppliFlex ST GMP is a configurable single-use bioreactor that meets all cGMP requirements for clinical production. The system simplifies Scale-Up, Scale-Down and Scale-Out. The fully closed system is customizable and reduces any risk of cross contamination.

The AppliFlex GMP is available in 500 mL and 3 L versions for both cell cultures and microbes.

SUPR single-use bioreactor

The SUPR single-use production bioreactor impresses with its simple, scalable and customer-friendly design. The cell culture reactor enables a seamless process transfer from R&D to production.

The SUPR bioreactor is available in the sizes 50L, 250L and 1000L.

Livit Flex bioprocess control system

The Livit Flex bioprocess controller is an intuitive and easily configurable bioprocess controller that fits any biotech upstream R&D application. Livit Flex can be configured as a single or dual control system for single-use or multi-use bioreactors to optimize bench space in the laboratory.

Livit Flex is ideal for use with single-use and reusable bioreactors up to 20L as well as our single-use pilot reactors.

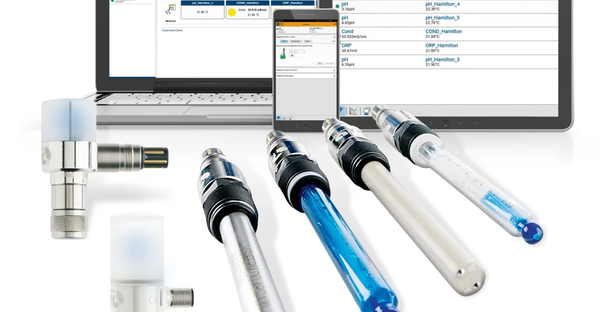

Hamilton ARC Sensors

Hamilton Arc simplifies the integration of sensors by revolutionizing the communication between sensors, end users and process control systems.

Whether pH, dissolved oxygen or cell density - all sensor values can be measured and transmitted digitally to the control unit in real time.

We are eager to receive your feedback

* Mandatory fields