Applications

The Future of Meat: How to produce Lab-Grown Meat

The scientific technology behind meat cultivation in a lab, crucial for artificial meat production, involves advanced cell culture and tissue engineering. Here's a brief overview:

- Cell Culture: This technique involves growing cells in a controlled environment outside their natural setting. For lab-grown meat, this typically starts with harvesting stem cells from animals.

- Tissue Engineering: These cells are then cultivated to multiply and differentiate into muscle fibers, the primary component of meat. In case a structured piece of meat is the end product, the process requires a scaffold where cells can grow to form tissue structures.

- Optimal Growth Conditions: Providing the right mix of nutrients, temperature, dissolved oxygen and pH levels is essential for cells to mature into meat. Bioreactors are used to maintain these conditions, allowing cells to develop as they would inside an animal.

The Cultured Meat Process Explained

The cultured meat process, also known as cultivated meat or artificial meat process, fundamentally begins with the extraction of cells from animals. These cells, often muscle or stem cells, form the basis of growing meat in a lab environment. Here's an overview of the process:

- Cell Selection: Cells suitable for meat production are harvested. These are usually muscle stem cells which are capable of differentiating into muscle tissue.

- Cell Cultivation and Proliferation: The selected cells are then cultivated in a controlled environment, typically a bioreactor, where they are provided with ideal conditions for growth, including temperature, oxygen, pH and a nutrient-rich medium.

- Differentiation: Once a high cell density has been reached by cell proliferation, the cell differentiation takes place. Inside the bioreactor, these cells differentiate, meaning they develop into different muscle fiber types. These muscle fibers are essentially the building blocks of meat.

- Harvesting: Over time, these fibers accumulate to form meat tissue. The process can take several weeks, after which the lab-grown meat is harvested. Different process types such as batch, fed batch, perfusion or chemostat processes are applied.

- Post-harvest processing: As with conventional meat products, the texture, taste and nutritional properties of the lab grown meat can be modified after harvesting. This also includes the enhancement with other cell types such as proliferated fat cells.

- Product Development: Finally, the lab-grown meat is prepared and tested for consumption, ensuring it meets safety and quality standards. Currently, authorization procedures are in progress in various countries to define the required quality standards.

This method, while still in developmental stages, represents a significant progress in sustainable food technology, aiming to produce meat with a lower environmental impact and without the ethical concerns associated with conventional animal farming.

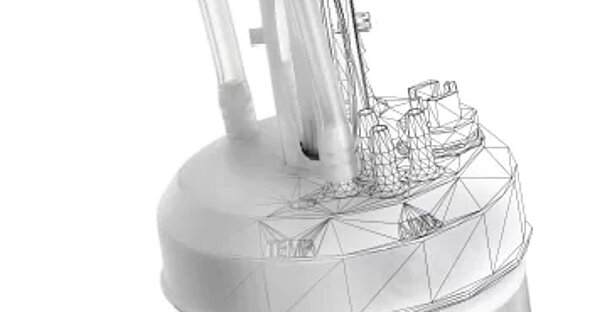

Applikon Mini Bioreactor: The start of a successful cultivation process

The Applikon Mini Bioreactor plays a crucial role in the field of artificial meat production, particularly in the area of research and development of lab meat. It's designed to cultivate animal cells, necessary for creating lab-grown meat, through a controlled and efficient small scale process. Here's an outline of how it works in this context:

- Cell Incubation: The small bioreactor provides an optimal environment for the initial cell cultures with a minimal working volume. These cells are the base of meat production.

- Controlled Growth Conditions: The Mini Bioreactor maintains precise control over temperature, pH levels, oxygen, and other critical parameters to ensure the best growth conditions for the cells.

- Scaling Up: As the cells multiply, the bioreactor supplies optimum growth conditions, allowing for the scale-up from a few cells to a substantial amount suitable for meat production.

- Monitoring and Optimization: Throughout the process, the bioreactor’s advanced control systems allow for continuous monitoring and adjustments, ensuring the cells develop efficiently into muscle tissue needed for meat.

This technology represents a significant advancement in producing meat without the need for traditional animal farming, aligning with sustainable and ethical food production goals.

Feautured Products

AppliFlex ST single use bioreactors

Thanks to 3D printing technology, each AppliFlex ST bioreactor can be uniquely configured to your individual process which includes custom impeller designs and various port connections.

The AppliFlex ST bioreactors come in 500 mL, 3 liter and 15 liter volumes. They are produced according to the high-quality Applikon standard and are interchangeable with Applikon’s glass bioreactors of the same volume.

BioSep perfusion device

The Applikon BioSep System is a unique cell retention system for perfusion processes. By using high-frequency ultrasonic resonance waves for cell separation instead of a physical membrane, the system offers all the advantages of conventional devices, but without their typical limitations.

The Biosep system is mainly used for cell cultures and yeasts, and plant cells.

Mini bioreactors MiniBio

The MiniBio is a true scale down of the traditional lab-scale bioreactor. The reactor is available in 250 mL, 500 mL and 1000 mL volumes and customizable to meet the demands of any bioprocess. It saves time, requires minimal bench space and generates more data with fully scalable results.

Despite its small footprint, the MiniBio can meet any process requirements. Whether for Batch, FedBatch or perfusion processes.

Stainless steel bioreactors

Stainless steel bioreactors play a key role in the development and production biotech products. From bench to pilot to full production – the Applikon bioreactors simplify your scale-up through consistent design and scalable control solutions.

Our portfolio offers both standard systems for fermentation and cell cultures as well as customized systems.

Glass autoclavable bioreactors

The Applikon autoclavable bioreactor is a very popular bioreactor. It is available in 2, 3, 5, 7, 15 and 20-litre volumes. It is easy to adapt if your research changes. Thanks to the modularity and flexibility of the glass bioreactors, you can modify the system to fit any adaptations in process demands.

The glass bioreactors help support and optimise your research and process development. The systems are suitable for both cell culture and microbial culture applications.

Livit Flex bioprocess control system

The Livit Flex bioprocess controller is an intuitive and easily configurable bioprocess controller that fits any biotech upstream R&D application. Livit Flex can be configured as a single or dual control system for single-use or multi-use bioreactors to optimize bench space in the laboratory.

Livit Flex is ideal for use with single-use and reusable bioreactors up to 20L as well as our single-use pilot reactors.

my-Control

This colorful controller with the built-in web server is the ideal solution for small scale bioreactors starting at 50mL working volume. It uses minimal bench space and allows parallel bioprocessing for microbial as well as cell cultures.

The myControl is the perfect solution for screening, process optimization or media development.

We are eager to receive your feedback

* Mandatory fields