Stainless steel bioreactors

to meet your every need

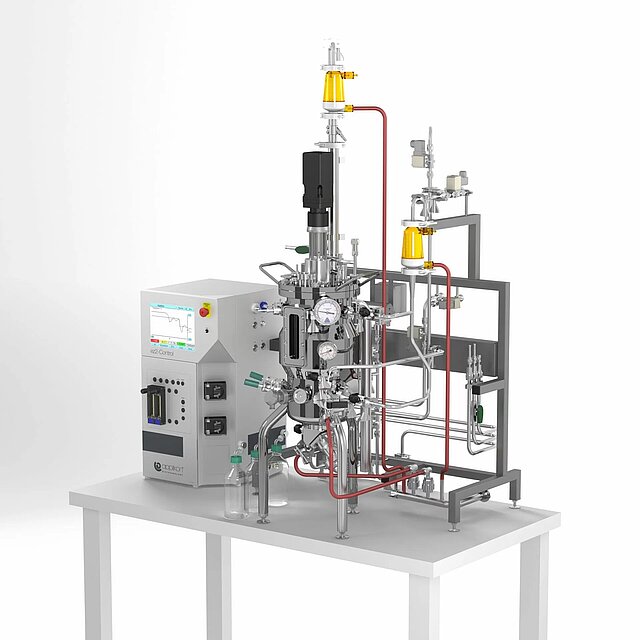

Stainless steel bioreactors are at the core of every biotechnology system. Therefore, you need them to be highly modular, adaptable and user-friendly to create an efficient and accurate process. Applikon bioreactors are easy to set up and provide an introduction to Sterilizatrion-in-Place (SIP) bioreactor regimes. This applies to the standardized BioBench and BioPilot, plus the tailor-made BioProduction systems.

Standardised and tailor-made systems.

Whether you need a quick, standardised solution, or a completely customized system, the stainless steel bioreactors from Applikon can help you make the most of your process. All bioreactors are designed and built to the latest hygienic processing standards. Plus, your validation of the system is simplified with a cGMP compliant design complete with documentation.

Compact design

The Applikon stainless steel bioreactors are a great fit if you are worried about bench or floor space. Their compact footprint means they occupy minimal space in the lab, without compromising on quality.

Scale up your bioprocess

From bench to pilot to full production – the Applikon bioreactors simplify your scale-up through consistent design and scalable control solutions. The standard bioreactors come in a wide range of volumes for both microbial and cell culture applications. Additionally, as a trusted pilot scale bioreactor manufacturer, Applikon offers various standard add-on modules to help you customize the stainless steel systems to meet specific application demands.

Features of the Applikon stainless steel bioreactors.

You can be sure that every bioreactor by Applikon, a leading SST (stainless steel) fermenter manufacturer, follows a consistent concept with exceptional features that make it stand out as a high-quality, efficient system. Below you will find some features of the bioreactor range:

Modularity.

The entire range of Applikon products is based on modularity, where standard modules are used to customize the functions of a product. The BioBench and BioPilot are no different. There are many add-on packs available that help you customize your Applikon bioreactor system to meet your specific demands.

These add-on packs include:

- Pressure control

- Weight control

- Feed control

- Biomass sensors

- Perfusion systems

- …and many more.

| Name and Total Volume | Working volume range | Height over diameter |

|---|---|---|

| BioBench 15L | 4 – 12 L | 2.2 |

| BioBench 20L | 4 – 17 L | 3.0 |

| BioBench 30L | 7 – 22 L | 2.0 |

| BioPilot 30L | 7 – 20 L | 1.5 |

| BioPilot 40L | 9 – 34 L | 3.0 |

| BioPilot 60 L | 10 – 40 L | 1.5 |

| BioPilot 70 L | 13 – 50 L | 3.0 |

| BioPilot 130 L | 21 – 100 L | 1.5 |

| BioPilot 140 L | 32 – 100 L | 3.0 |

| BioPilot 270 L | 40 – 200 L | 3.0 |

| BioProduction | Any volume that suits your needs, up to 5000 liter total volume (larger volumes possible by arrangement) |

Tailor-Made solutions

For those who need large-scale productions, you can choose a completely customized solution. Using modern technologies, advanced communication tools, verification tests and full documentation, the entire process is easy. From initial idea to final product, we can help make a system that exceeds your expectations.

Furthermore, our highly trained team at Resea Biotech guarantee the best after sales support to ensure your systems stay in optimal working condition throughout its lifecycle.

Industrial control solutions for every need.

For the stainless steel BioBench, BioPilot and BioProduction, there is a selection of hardware and software available to control the bioreactors.

The dedicated controllers for the bioreacors are:

However, combination packages of hardware and software are also available. These inclue:

On top of controllers, you can also be sure your sensors are of the highest quality, thanks to the collaboration with prominent sensor suppliers. The following are available as options for Applikon bioreactor systems:

Results that are easy to reproduce.

With an easy set-up and using state-of-the-art controllers, you can enable precise control of your fermentation or cultivation run. This allows you to produce reproducible results every single time.

Easy to use and clean.

Applikon stainless steel bioreactors are designed for ease of use. All bioreactors come with an electropolished surface finish of Ra ≤ 0.4 micron. This means any biofilms or debris will not stick to the inside of the bioreactors and significantly simplifies the cleaning procedure of the BioBench, BioPilot and BioProduction systems. You can have peace of mind knowing your bioreactors will always be clean and sterile.

FAQ’s about the stainless steel bioreactor systems

Below are frequently asked questions about the BioBench, BioPilot and BioProduction systems.

The stainless steel bioreactors are suitable for use in the following applications:

- Scale-up studies

- Medium optimization

- Process optimization

- Small scale production

- Microbial and Cell culture

- Batch, Fed-Batch, Perfusion and Continuous cultivation.

The BioBench bioreactor is available in:

- 15 L

- 20 L

- 30 L

The BioPilot bioreactor is available in:

- 30 L

- 40 L

- 60 L

- 70 L

- 130 L

- 140 L

- 270 L

The BioProduction tailor-made bioreactors are available in any volume you choose, up to 5000 liters.

You can use the dedicated ez2-control and i-control controller software with all Applikon bioreactors.

Click here for more information on controllers and softwares.

Yes! The BioProduction stainless steel bioreactor is a tailor-made solution to fit your exact bioprocess needs.

Contact our team to start the process of creating your customized bioreactor system.

An essential tool for the bioprocess.

Applikon stainless steel bioreactors are an essential tool for your bioprocess. Whether small-scale or large-scale production, these bioreactors help produce the best results from both microbial and cell culture applications.

The Resea Biotech support team will be happy to help you find the right system for your and will assist you every step of the way. Hundreds of high-quality Applikon bioreactor systems have been supplied to the global biopharmaceutical industry. Add yourself to the list!

Facts and Figures

Applications:

- Scale-up studies

- Medium optimization

- Process optimization

- Small scale production

- Microbial and Cell culture

- Batch, Fed-Batch, Perfusion and Continuous cultivation

Volumes:

- Standard Volumes

- Cell culture:

15L, 20L, 30L, 60L, 130L, 270L - Microbial:

15L, 20L, 30L, 40L, 140L, 270L

- Cell culture:

- Custom build units up to 5'000 L

Dedicated controller:

Category:

Applikon BioBundle Paketlösung, Applikon Bundle Turnkey Solutions, Applikon Bioreactor Systems

Applications:

Process development, Research Optimization, Pilot Plant, Manufacturing

Cultivation Volumes:

Types:

We are eager to receive your feedback

* Mandatory fields