Applikon AppliFlex ST - fully customizable, single-use bioreactor.

The Applikon AppliFlex ST (stirred tank) bioreactor is changing the game. It’s designed on demand and is ready for use straight from the box. Using 3D printing technology, each AppliFlex ST bioreactor can be uniquely configured to your individual process which includes custom impeller designs and various port connections. Build the bioreactor of your dreams with this great addition to the innovative Applikon family!

Box-To-Bench workflow with disposable bioreactor systems

The AppliFlex ST continues Applikon’s trademark “Box-To-Bench” workflow. It allows you to dive straight into your bioprocess thanks to a quick setup and easy operation. The bioreactor can be taken directly from its box and used on the benchtop straight away. When you’re finished, simply dispose of the bioreactor according to the instructions and grab another one to start a new run.

3D Printed Custom Design

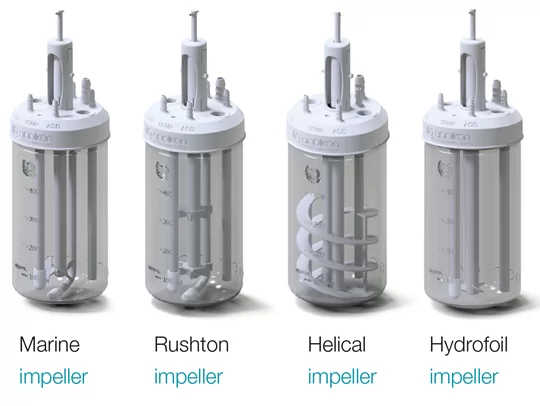

The choice is in your hands with the AppliFlex ST! You get to choose:

- Type and number of impellers

- Number of liquid and gas additions

- Type of sparger best suited to your bioprocess

- Any other change of the top plate you can think of

Plus, the 3D printing production technology guarantees reproduction reliability, with identical conditions between runs.

GMP Version available

The single-use bioreactor for clinical applications. The AppliFlex ST GMP* is a customizable disposable bioreactor that is designed to meet all cGMP requirements for clinical CGT applications. It enables a seamless process transition from R&D to clinical production.

Interchangeable tanks with various volumes

The AppliFlex ST bioreactors come in 500 mL, 3 liter and 15 liter volumes. They are produced according to the high-quality Applikon standard and are interchangeable with Applikon’s glass bioreactors of the same volume. All the measurement and control auxiliaries are also interchangeable, meaning you can switch it up between single-use and reusable systems with little extra time and no extra cost!

Optical or Classical Sensor Technologies

Choose between optical or classical sensor technologies when configuring your single-use bioreactor.

Classical sensors include:

- pH

- Dissolved Oxygen

- Temperature

- Optical density

- Biomass (Capacitance)

- RedOx

- …and more!

Optical sensors make operating the bioreactor systems even easier through barcode calibration on the vessel. They include:

- pH

- Dissolved oxygen

- Temperature

- Optical density

Applications for the AppliFlex ST

Cultivate anywhere! No laminar flowhood, water supply or drain is required to use the AppliFlex and there are several perfusion potions available for continuous bioprocessing.

The AppliFlex ST bioreactors are also adaptable to different applications. Use them for:

- Microbial and Cell culture

- Regenerative medicines and Stem cell cultures

- Cell and gene therap

- mRNA synthesis

- Batch, fed-batch, perfusion and continuous cultivation

- Screening studies

- Media optimization

- Process optimization

Features of the AppliFlex ST

Optimize your upstream hardware bioprocess with Applikon’s AppliFlex ST. As a fully customizable stirred tank bioreactor, the AppliFlex stands out from other disposable bioreactors.

Custom Design

Everything from the head plate to the impeller design is customizable on the AppliFlex ST range of bioreactors, making them perfect for any small scale or lab scale environment. It’s also incredibly easy to configure a new bioreactor for a new process.

Optimized Workflow

The single-use AppliFlex range has a scalable stirred tank vessel design and is available for use in both Microbial culture or Cell culture applications. Further optimise your workflow with the simple calibration of single-use sensors and easy to open design for the end of the run.

Single-Use

Due to the single-use nature of the AppliFlex from the well-known manufacturer Getinge, there is no cross-contamination and the bioreactors arrive in your hands pre-sterile and ready to go! With a lower initial investment, you also save costs and time.

FAQ’s about the AppliFlex ST bioreactor

It’s simple! In order to make sure we get everything right, we’ll send you a questionnaire on your needs for the bioreactors. Then, we’ll have a further conversation on the possibilities and how we can help you build your ideal single-use bioreactor. This ensures you’re getting exactly what you require for your environment and processes.

No. Since the AppliFlex ST comes pre-sterilized, it cannot be sterilized again after use. Therefore, the AppliFlex range of bioreactors are single-use only.

The sterility AppliFlex ST bioreactors are guaranteed for two years after the initial sterilization date.

Of course! Bundles and add-on packs are available for my-Control and ez2-Control as well as the new Livit Flex Controller, Applikon’s own software designed for bioprocesses. There are also retrofit packs for my-Control and retrofit packs for ez-Control will be available.

Delivering a customized single-use bioreactor relies on a good design with all customer specifications. After this is approved, production, assembly, sterilization and shipment can commence. In total, this process takes between 8 to 12 weeks.

Find more FAQs on the application and customization of the Applikon AppliFlex ST here.

Conclusion headline

With the Applikon AppliFlex, you don’t have to make any compromises in the design of you bioprocess. You can make the risk of cross-contamination between runs a thing of the past! It also alleviates time-consuming cleaning and sterilizing since the system will be disposed of after use.

Facts and Figures

Applications

- Microbial and Cell culture

- Regenerative medicines & Stem cell cultures --> GMP Version available!

- Batch, Fed-Batch, Perfusion and Continuous cultivation

- Screening studies

- Media optimization

- Process optimization

Volume:

- 500mL, 3L and 15L

Dedicated controller:

Category:

Single-Use Bioreactors, Applikon Bioreactor Systems

Applications:

Process development, Research Optimization, Fundamental, Screening

Cultivation Volumes:

Types:

We are eager to receive your feedback

* Mandatory fields